Why permanent identification matters in harsh test environments

Why this matters more than you think

While often overlooked in technical literature, the way accelerometers are marked has real-world consequences. Users frequently raise the issue, particularly when it comes to lost serial numbers and equipment traceability.

The risk with laser marking

Most accelerometer manufacturers use laser engraving to add part numbers, logos, and serial numbers. It’s a fast and precise method, capable of etching complex designs into titanium and other hard metals.

But here’s the issue: laser marking can wear off, especially under tough operating conditions.

Accelerometers are regularly exposed to extreme environments, rough handling, and the wrong adhesives applied to unintended surfaces. Over time, cleaning these adhesives can erase laser-marked information, including the crucial serial number.

Why serial numbers matter

Without a serial number, an accelerometer loses its full traceability:

- Calibration records

- Build and specification history

- Performance documentation

At DJB, we can provide calibration sensitivity for every sensor we’ve ever manufactured, dating back to 1974 — but only with the serial number. If that number wears off, the sensor becomes almost unusable.

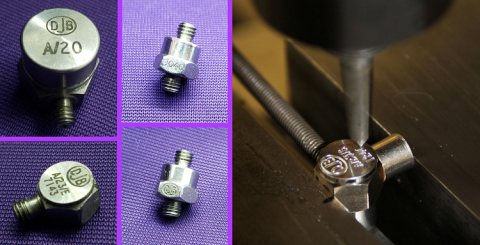

Our solution: old-school mechanical engraving

At DJB, we mechanically engrave our accelerometers. That means serial numbers are deeply etched into the metal itself — they can’t wear off. Even after years of use in harsh environments, our sensors remain fully identifiable.

Just check the image examples — the accelerometers are dented and scratched, but every serial number is still intact.