Training course: Introduction to rotating machinery vibration diagnostics

Date: 12-14 November 2024

Duration: 3 days

Location: Torrington, Devon, UK

Organiser: Beran

Mastering vibration analysis: Enhance your diagnostic skills

Introduction

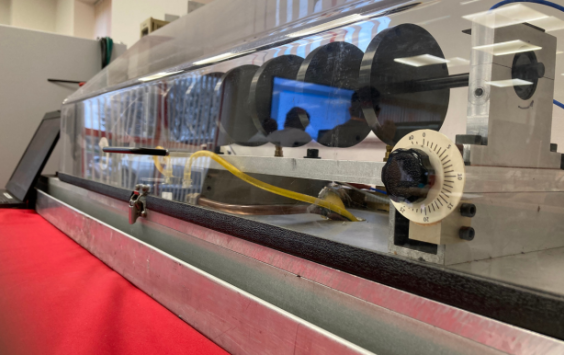

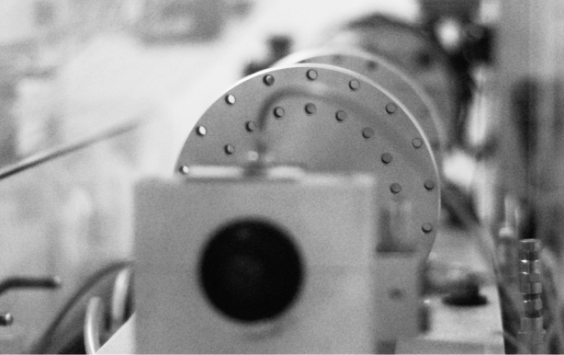

Unlock the full potential of your Beran PlantProtech online vibration and condition monitoring systems through our comprehensive three-day training course. Held at our headquarters in Torrington, Devon, this course offers invaluable insights into optimising plant operations.

About the course

Tailored for non-practitioners, this course aims to equip attendees with the knowledge necessary to safely manage and operate plant machinery while effectively communicating with specialist vibration engineers.

Target audience

Ideal for system engineers, mechanical engineers, and operations staff, including new hires, trainees, and apprentices. No prior experience in vibration or condition monitoring theory is necessary.

Trainers

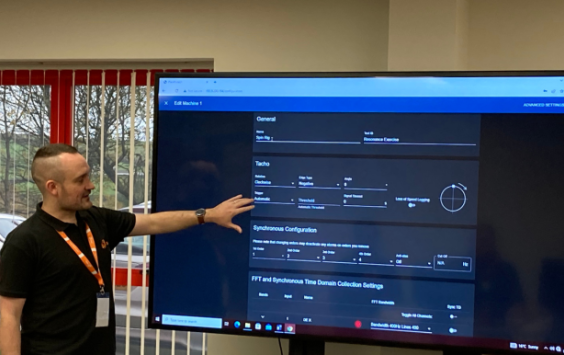

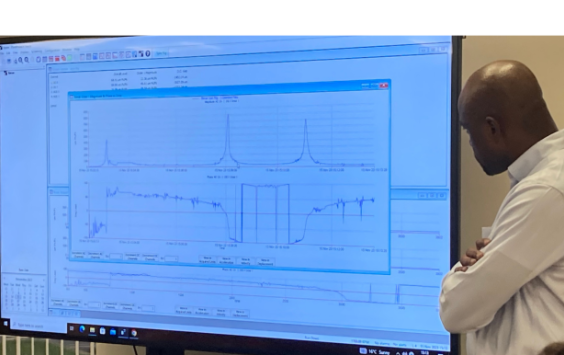

Gain essential skills in vibration monitoring and diagnosis from industry experts Craig Hill, Beran's internal expert, and Omoruyi Onobhamiukor, CEng MIMechE.

Omoruyi Onobhamiukor

Omoruyi Onobhamiukor, CEng MIMechE, Head of Asset Performance Management at Uniper. With extensive mechanical engineering experience in the power industry, Omoruyi is a seasoned expert in power plant asset monitoring and a member of ISO and BSI vibration analysis committees.

The instructor, Omoruyi Onobhamiukor, was incredibly knowledgeable and delivered the course content in a clear and engaging manner. I left with a solid understanding of vibration analysis and its practical applications.

Craig Hill

Craig Hill, Beran's Electrical Installation and Service Team Leader, will present this course alongside Omoruyi. With more than 10 years of experience, Craig is adept in electrical installation and service leadership. His expertise includes extensive site works, onsite calibration procedures, and working with Beran PlantProtech™ systems. Craig has also contributed significantly to the development of our training services, enhancing both team and client skills.

The Beran training course was informative and well-presented. It's been instrumental in my professional development.

Learning objectives

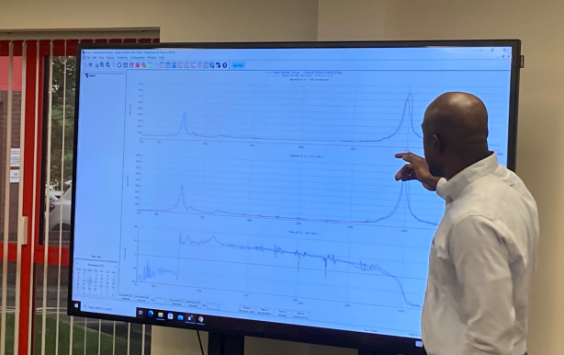

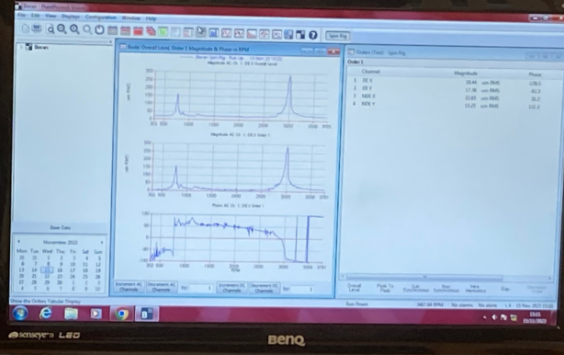

- Interpret vibration data effectively.

- Select optimal display formats for various scenarios.

- Utilise historical data for predictive analysis and leverage advanced system features.

Included

- Certificate of Attendance

- Rotor Dynamics Manual

- Refreshments and buffet lunches

- Full factory tour

Cost

£2,212 per person, with a 10% discount for group bookings of three or more.

Attendee testimonials showcase

I highly recommend this course to anyone looking to enhance their knowledge of vibration diagnostics. The engaging delivery and hands-on experience made learning enjoyable and effective.

Attending this course was invaluable for our team. The practical sessions and real-world examples helped us apply the concepts directly to our plant operations.

Register your interest today for an enriching learning experience!