Beran, a leading manufacturer, specialises in online condition and vibration monitoring machinery protection systems for critical infrastructure worldwide. Headquartered in the UK, we operate globally with dedicated sales and service divisions in the USA, Germany, France, and Italy, complemented by an extensive network of distributors across the globe.

Discover the highlights from the Beran Conference 2024 at Chatsworth House!

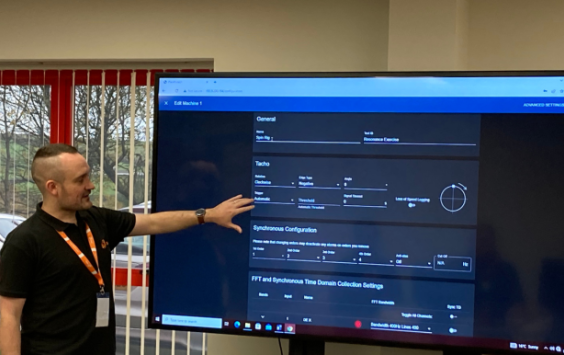

From insightful presentations to groundbreaking innovations, industry leaders and experts came together to shape the future of condition monitoring. Attendees had the opportunity to explore cutting-edge products, delve into real-world case studies, and preview the next iteration of PlantProtech™ Vision software.

Set against the stunning backdrop of Chatsworth House, the event fostered valuable networking and collaboration among global professionals.

Ensuring proactive maintenance and machinery reliability

Find out more about how SSE Thermal used site engineers, continuous online vibration and condition monitoring systems with specialist remote diagnostic engineers' support.

This study emphasises the critical role of site walk-downs performed by engineers and the integration of continuous monitoring systems, enhancing the reliability and safety of machinery through proactive maintenance strategies.

Online monitoring systems for your strategic rotating plant

Strategic rotating plant monitoring made seamless with our PlantProtech™ hardware and software family. Deployed globally, our state-of-the-art systems are currently active in more than 500 power industry installations worldwide

Experience the versatility of our robust portable condition and vibration monitoring system designed for strategic plant items, offering both real-time and remote diagnostic capabilities.

Elevate monitoring capabilities for strategic plant items with our versatile automated surveillance system, designed to meet the demands of increased monitoring needs.

Fulfil your measurement needs with our shear mode vibration sensors. Streamline your installation process with our range of high-quality cables and accessories.

Piezocryst specialises in crafting high-precision pressure sensors and accelerometers tailored for demanding applications.

ENGIE Laborelec offers a suite of detection and protection solutions designed to counteract harmful torsional vibrations in shaft lines.

Welcome to Beran, where excellence meets commitment in providing top-tier service and support for power industry solutions. As leaders in online condition and protection monitoring products, specialising in turbine monitoring, we are dedicated to ensuring your operations run smoothly and efficiently.

Explore our comprehensive range of services designed to exceed your expectations, from technical support and onsite calibration to maintenance packages and software upgrades. Partner with Beran to unlock unparalleled expertise and reliability in the industry.

Vibration Training Course, November 2024

Date: 12-14 November 2024

Duration: 3 days

Venue: Torrington, Devon, UK

Limited spots are available! Reserve your seat now to enhance your skills and drive performance in machinery maintenance.

At critical infrastructure sites, various control and instrumentation systems are deployed throughout the plant. Over time, these systems may become obsolete or lack support from the original equipment manufacturers for various reasons.

Leveraging our expertise, Beran specialises in the support of ageing and obsolete electronic systems at Nuclear Energy Plants, ensuring continued operation for key infrastructure sites. Our approach offers a cost-effective solution, avoiding the need for complete system replacements.

Automate the calibration of vibration sensors and measurement microphones to ISO standards with TransCal™—Beran's trusted platform for transducer calibration systems.

The Beran 402 stands as a dedicated laboratory high-precision instrument designed for accurately measuring the frequency response of dynamic systems.