Protection and condition monitoring systems are essential to monitor critical assets and understand machinery health for long-term safe, efficient operation by plant owners and operators to prevent machine failure, and planning maintenance tasks and activities.

Automated vibration trip system providing API670-compliant (American Petroleum Institute) machinery protection with integrated condition monitoring functionality.

The Structural Health Monitoring System (SHMS) is SEI’s airborne solution for tracking structural performance as part of its Health and Usage Monitoring System (HUMS).

With a compact, lightweight design and low power requirements, SHMS includes a Data Acquisition and Processing Unit (DAPU), Data Storage Unit (DSU), and optional Control/Display Unit (CDU), offering a versatile, high-performance platform for capturing, storing, and viewing critical structural data in flight.

The Rotortuner Balancer (RT-Balancer) is a portable or semi-permanently installed Propeller Balance and Vibration Analysis system for use on fixed-wing propeller aircraft.

The Rotortuner Line Scan Camera is an advanced blade tracking sensor that measures rotor blade height and lead/lag in flight.

RT-JEM has been developed to meet engine manufacturers' exacting requirements for run-up, run-down, and steady-state vibration monitoring.

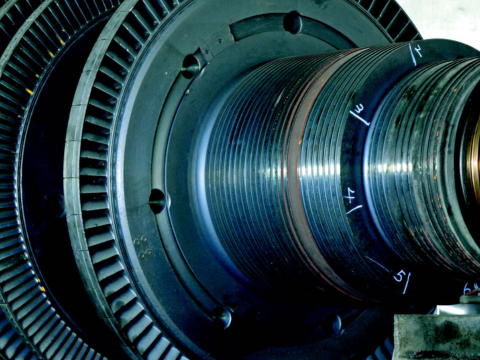

Detecting and addressing harmful torsional vibrations in shaft lines

TORSO’s automatic detection and protection functionality eliminates your worries about excessive torsional vibrations in today’s situation of constantly changing grid circumstances.

TORSO Detect simply plugs into your existing system and monitors the torsional vibrations using the available array of sensors. It is an affordable early-warning system that enables you to take measures if needed.

Open description configuration options

A range of accelerometer types may be used with the Rotortuner equipment, with low-frequency balance accelerometers being the norm (0-10kHz).